If the welded pipe cannot be straightened, first check the used high frequency welded pipe equipment to see if the problem lies in the sizing. Because the sizing is a very important point that affects the straightness of the welded pipe.

Prerequisites for straightening: From the production practice of used high frequency welded pipe equipment, sometimes the straightening head cannot be straightened, and sometimes it can be straightened with a slight adjustment, which shows that there are prerequisites for smooth straightening.

Prerequisites for straightening welded pipes with used high frequency welded pipe equipment

Prerequisites for straightening:

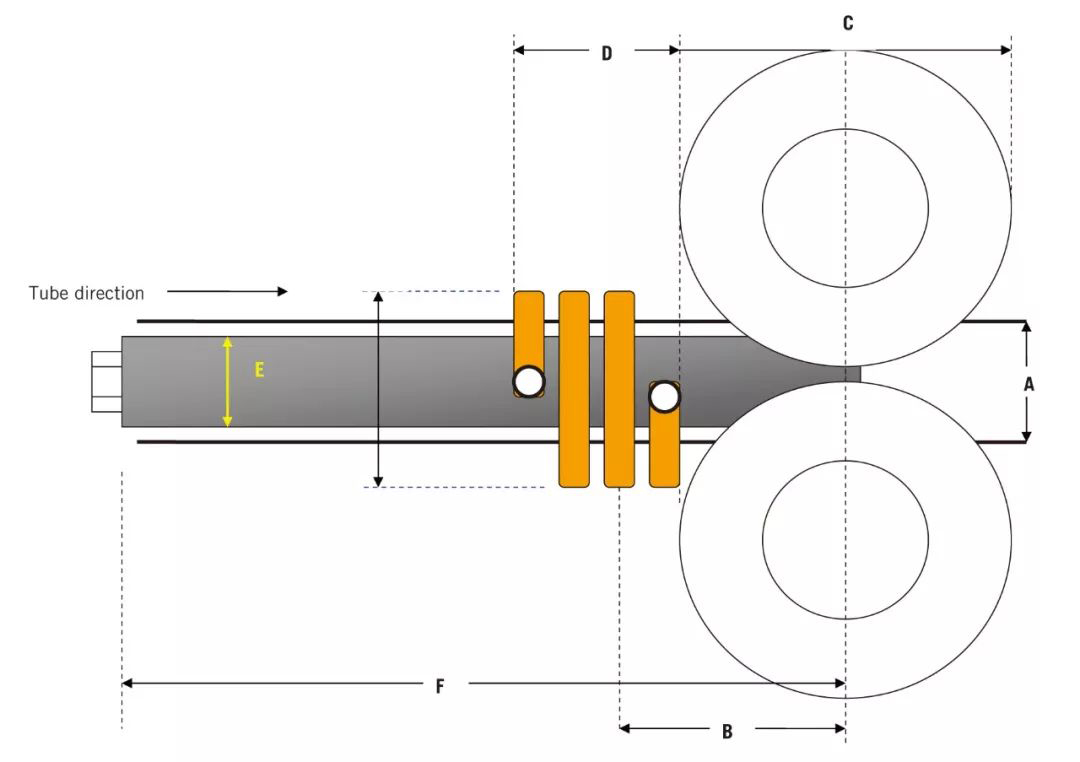

(1) Sizing machines must be used. Sizing machines actually provide two fixed fulcrums for straightening (for two-roller and four-roller straightening heads), which cooperate with the active fulcrum of the straightening head to form two unidirectional force points and one opposite force point to act on the pipe body together to complete the straightening. Therefore, whether it is two-roller, four-roller or eight-roller, sizing machines must be used to complete it. Another meaning of using the sizing machine for adjustment is that the size and direction of the straightening force (forming rolling force) provided by the sizing machine must be stable. This is also the reason why the straightness of the welded pipe will bend and swing once the sizing machine is unstable.

(2) The stress size and direction distribution on the welded pipe in the sizing machine must be stable. The reason why the welded pipe can be straightened is that the size and direction of the straightening force applied by the straightening head and the stress inside the welded pipe in the sizing machine reach a short-term dynamic balance. Once this balance is broken, such as changes in the thickness of the pipe blank, changes in the coolant flow, changes in welding heat (high-frequency power), damage to the roller bearing, etc., the originally straight welded pipe will immediately bend. The size and direction of the force applied to the welded pipe must be changed by the straightening head to regain balance before the welded pipe can restore its straightness.

(3) The weld position must remain stable in the sizing machine. According to the welding principle and welding process, there is a welding heat affected zone at both ends of the weld. Since this area absorbs a lot of heat energy during the pipe welding process, the heat-affected zone will inevitably accumulate a lot of shrinkage stress (compressive stress) during the rapid cooling process with the welded pipe (after the extrusion point). This stress with both size and direction forces the welded pipe to be sized to bend to one side of the weld. If the weld deflects, then the straightening force that was originally just right in force and direction is applied to a point where the force is not needed (may not be so large, or may not be in this force direction), thus breaking the previous stress balance and the welded pipe changes from straight to bent. Before the straightening head finds (manual intervention) a new balance point, the welded pipe is always in a bent state. If the weld position is always unstable, then the straightening head needs to constantly find a new balance point, and the welded pipe keeps changing between bending and straightness. Therefore, if you want the welded pipe to have a good straightness, you must first "fix" the weld position.

Therefore, if the welded pipe cannot be straightened, you need to check whether there is a problem with the sizing of the used high-frequency welded pipe equipment, and then do straightening work from the sizing to straighten the welded pipe and solve the problem of straightening the welded pipe.