- Home

-

Products

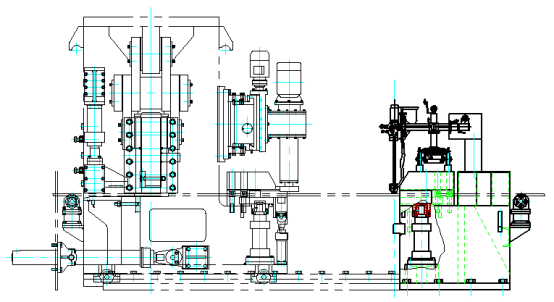

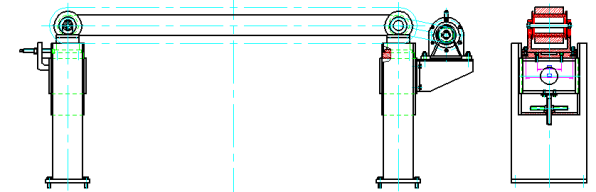

- Used Welded Pipe Machine

- Stainless Steel Cut-To-Length Line Unit

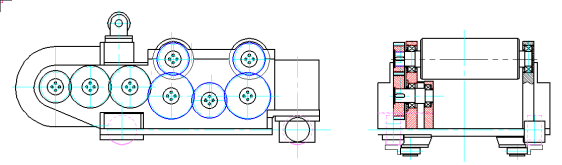

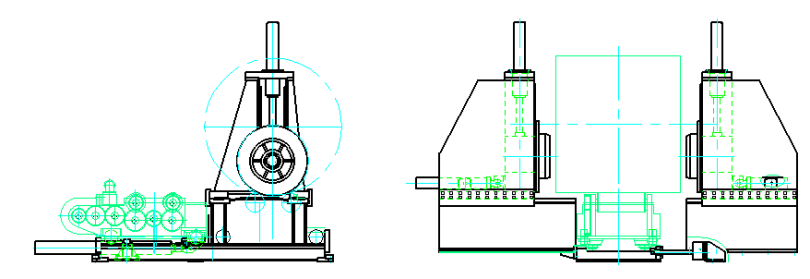

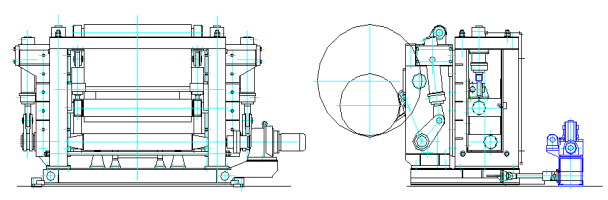

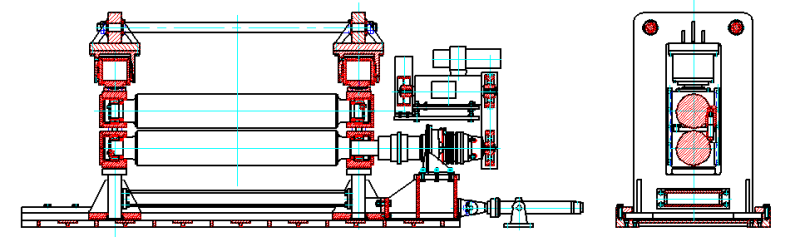

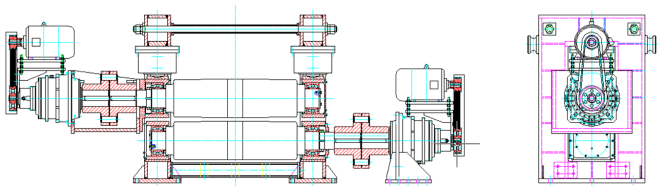

- High Frequency Pipe Welding Unit

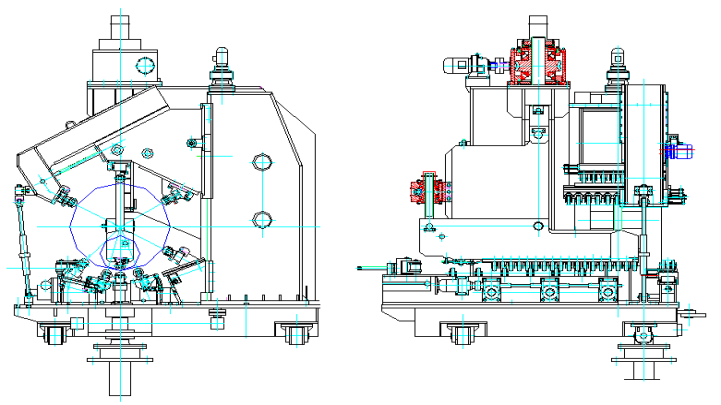

- High Frequency Pipe Making Machine

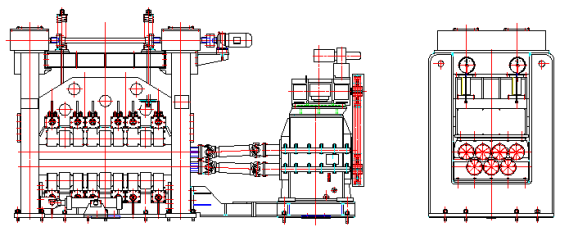

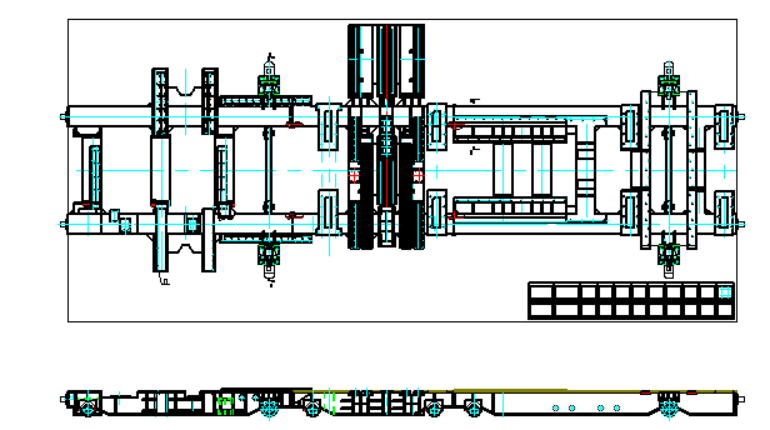

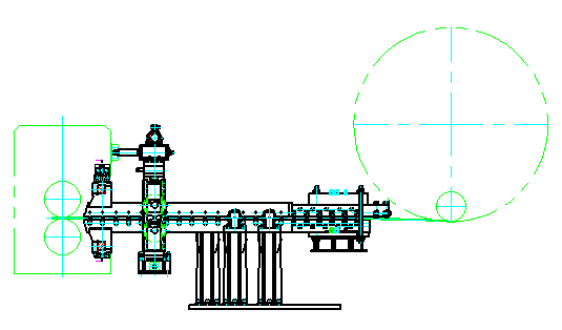

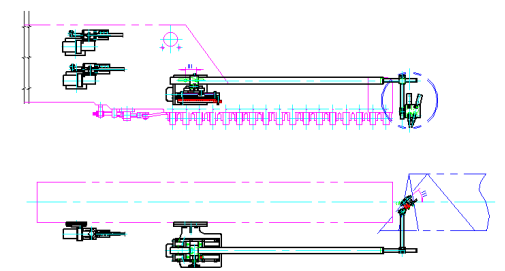

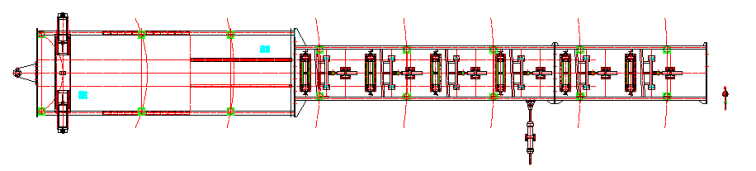

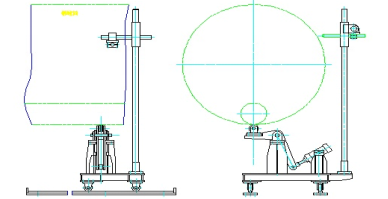

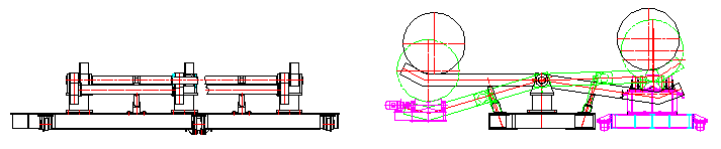

- Flying Welding Spiral Welded Pipe Unit Production Line

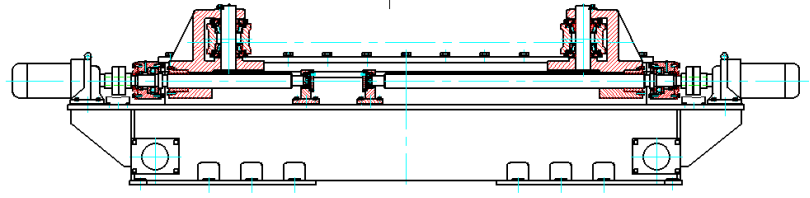

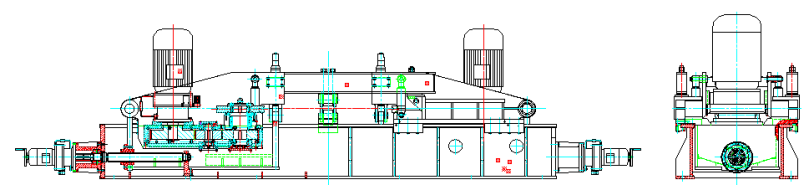

- 850mm Second-Hand Slitting Line

- 1650mm Second-Hand Slitting Line

- 2200X16mm Used Strip Steel Slitting Line

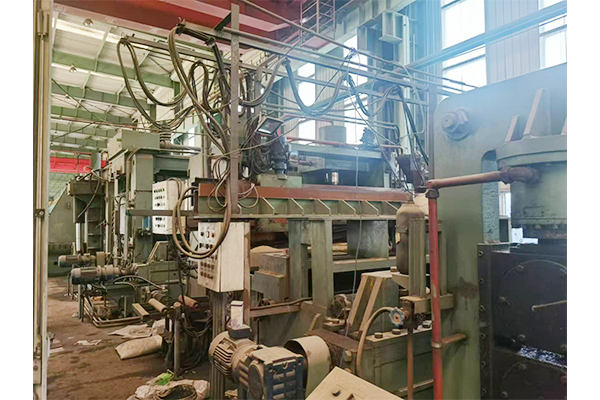

- Second-Hand Nanyang 50 Enlarge 76 High Frequency Welding Pipe Mill

- Used Welded Pipe Machine

- Stainless Steel Cut-To-Length Line Unit

- High Frequency Pipe Welding Unit

- High Frequency Pipe Making Machine

- Flying Welding Spiral Welded Pipe Unit Production Line

- 850mm Second-Hand Slitting Line

- 1650mm Second-Hand Slitting Line

- 2200X16mm Used Strip Steel Slitting Line

- Second-Hand Nanyang 50 Enlarge 76 High Frequency Welding Pipe Mill

- Display

- News

- About

- Partners

- Language