In the production of high-frequency welded pipes by used high-frequency welded pipe equipments, the removal of internal burrs has always been a difficult problem to solve, especially for small-diameter welded pipes. Larger and medium-diameter welded pipes are more prone to internal burr scraping, excessive or too small and insufficient scraping. Clean and other problems seriously affect the scraping quality of internal burrs and the quality of welded pipes. By briefly introducing the type of inner burr arbor and the structure of the small diameter HFW arbor, the author puts forward the common problems and solutions of the inner burr removal of the small diameter HFW welded pipe according to the production practice.

Types of Internal Burr Removal Toolholders

There are three types of internal burr removal toolholders for used high-frequency welded pipe equipments: ①Mechanical internal burr removal toolholders. ②Pneumatic internal burr removal tool holder. ③Hydraulic internal burr removal tool holder.

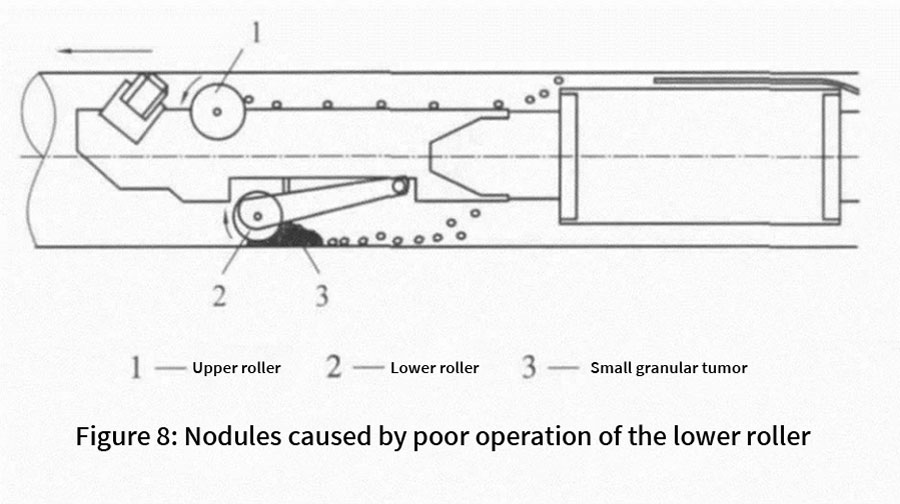

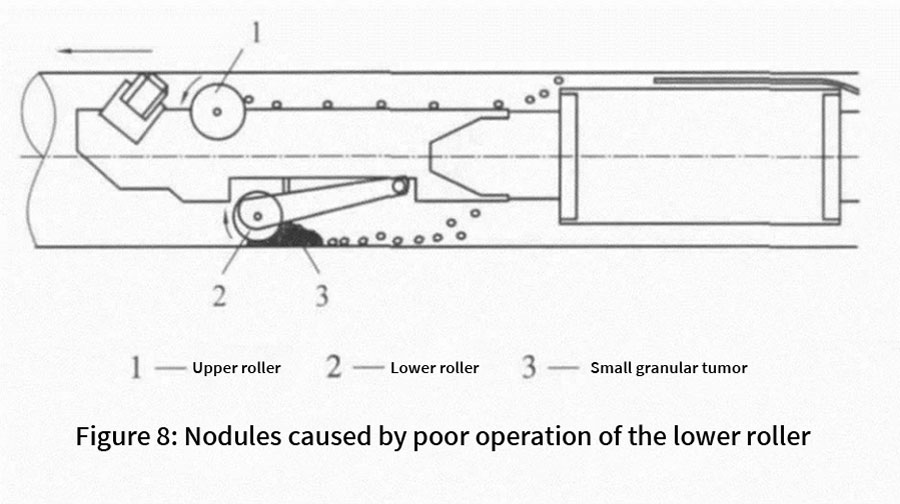

Mechanical internal burr removal tool holder. The lower roller of this type of cutter bar has an adjustable top wire to fix the height, and when removing the burr in the steel pipe with the standard 76~114mm, a mechanical cutter bar and a buffer spring are required.

The advantages of this type of tool holder: fixed size, simple structure, easy maintenance.

Disadvantages: Internal burr removal is unstable, poor compatibility. For products that do not require high internal burr removal accuracy, the strength of the steel pipe after removal is low.

Pneumatic internal burr removal toolholder. The lower roller of this type of cutter bar is controlled by adjustable air pressure, which is relatively stable when removing internal burrs, and has a simple structure and convenient maintenance. It is suitable for products that require high internal burr removal accuracy. However, it has the disadvantage of poor compatibility, and cannot remove high-strength steel pipes due to the limitation of air pressure.

Hydraulic internal burr removal toolholder. The lower roller of this type of cutter bar is controlled by adjustable oil pressure, so its working stability is good, and it is suitable for steel pipes, precision pipes and high-strength steel pipes that require high internal burr accuracy. However, its structure is complex, and the machining and manufacturing requirements of the tool holder are high.

Different used high-frequency welded pipe equipments has different ways of removing internal burrs. The cutter bar can effectively remove the burrs in the welded pipe, and it is what we need to make a qualified welded pipe.