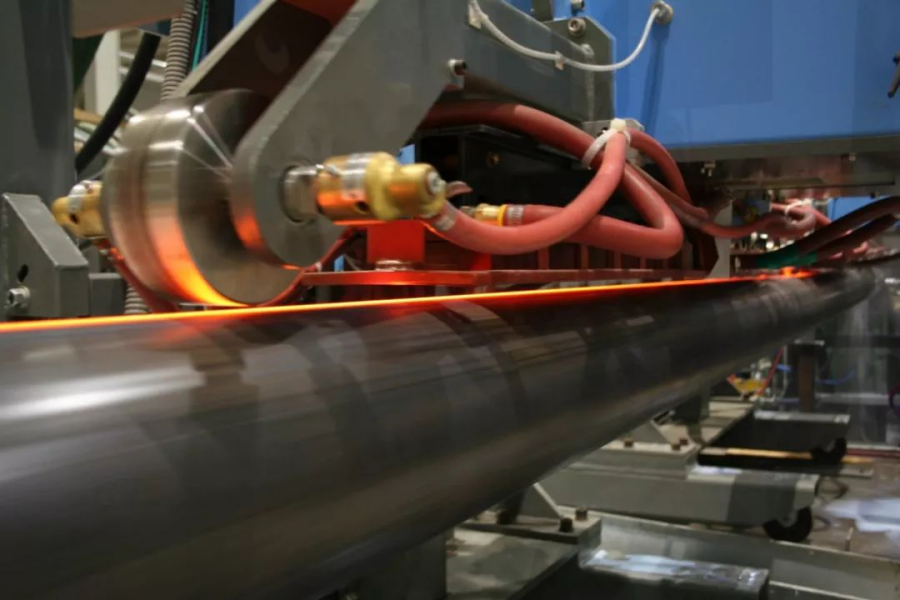

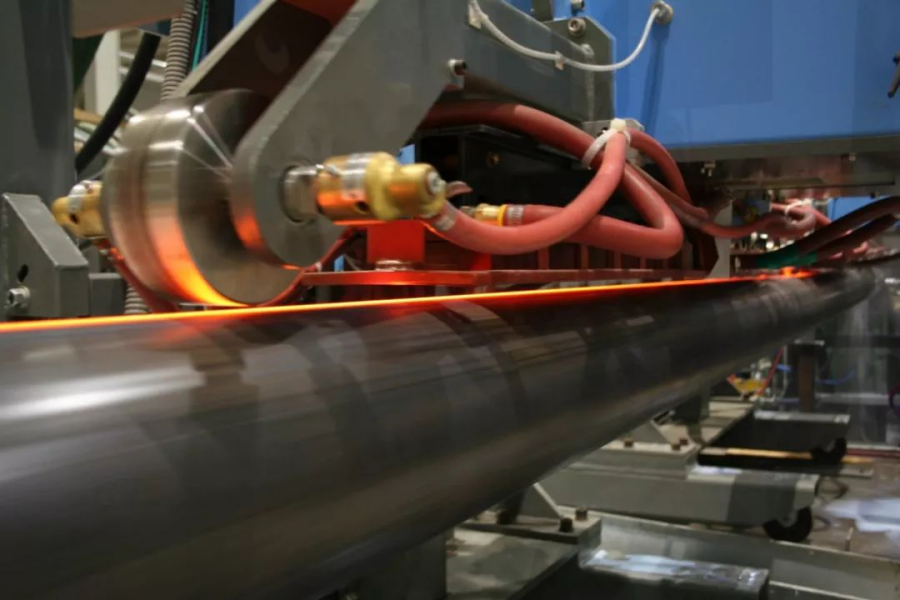

Internal burrs often appear when roll forming equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

There are 9 common problems in removing internal burrs with roll forming equipment: ① The output power is too large. ②Welded weld bead. ③ The inner burr ring knife breaks down. ④ The residual height of the inner burr exceeds the standard. ⑤ The weld is in the shape of a peach. ⑥The cutter bar cannot be lifted up and the burr cannot be scraped. ⑦ Internal burr scraping is periodic, scale-like and spiral-like. ⑧ Internal burr scraping deviation. ⑨ Other problems and solutions. According to these 9 kinds of common problems, we will explain to you the common problems of internal burr removal: the output power is too large and the welding seam is welded.

Excessive output power:

Due to the limited diameter of the small diameter HFW welded pipe itself, the built-in cutter bar will limit the cross-sectional area of the magnetic rod, resulting in low welding speed and excessive output power.

Solution:

(1) Try to choose a magnet rod with a larger diameter when space allows.

(2) The end of the magnet bar is aligned with the center of the squeeze roller.

(3) The gap between the magnet bar and the tube should be as small as possible, and controlled within 5-15mm.

(4) Choose a magnetic rod with a high Curie point temperature.

(5) Using an external magnetic rod.

(6) The magnetic bar increases the pressure of the cooling water and reduces the temperature.

(7) Reasonably choose the length of the magnetic rod and the number of turns of the induction coil (usually 2 to 5 turns).

(8) Select the opening angle reasonably, the smaller the opening angle, the stronger the proximity effect and skin effect.

(9) Reasonably select the distance between the induction coil and the center of the extrusion roller (the closer the better), the smaller the gap between the induction coil and the tube, the better, the best is 5-8 mm.

(10) Reasonably select the frequency of solid-state high frequency; do not pour cooling water directly to the weld; the weld is preferably cooled by inert gas.a

Welded weld bead:

When roll forming equipment is used to produce steel pipes with a wall thickness of 6-14 mm, due to the low welding speed and slow melting of the strip section, the phenomenon that the edge of the strip is melted first and the middle is not melted, resulting in a step temperature, which makes the strip melt. The high-temperature molten metal at the sharp corners of the steel edge flows to the center of the squeezing roller at the end of the magnet bar to instantly generate a weld flash.

Solution:

(1) Increase the cooling water pressure of the magnetic rod by 1 MPa, and wash away the welding tumor at the end of the magnetic rod.

(2) Add a horizontal compressed air pipe to the end of the magnetic rod to blow the welding tumor.

(3) The end of the magnet bar should not be placed in the center of the squeeze roller, and the placement position should be moved back by 20-30 mm.

(4) After the unit is running, after the vehicle speed and welding temperature are stabilized, the tool bar is raised to remove internal burrs.

(5) Use semi-melting welding to reduce the generation of molten metal slag.

(6) Using solid-state high-frequency and low-frequency welding, it can provide stable frequency and output power.

(7) Properly increasing the opening angle, that is, widening the width of the guide plate, reducing the fusion of the molten metal in front of the center of the extrusion roller, and making the strip steel converge in the extrusion roller.

(8) Appropriately increase the gap between the magnetic rod and the tube, and keep it at 15-20 mm.

(9) It can increase the welding speed, reduce the metal spatter, and avoid the generation of welding flashes.