Internal burrs often appear when used roll forming equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

There are 9 common problems in removing internal burrs with used roll forming equipment: ① The output power is too large. ②Welded weld bead. ③ The inner burr ring knife breaks down. ④ The residual height of the inner burr exceeds the standard. ⑤ The weld is in the shape of a peach. ⑥The cutter bar cannot be lifted up and the burr cannot be scraped. ⑦ Internal burr scraping is periodic, scale-like and spiral-like. ⑧ Internal burr scraping deviation. ⑨ Other problems and solutions. According to these 9 kinds of common problems, we will explain the common problems of internal burr removal: the welding seam is in the shape of peach and the burr cannot be scraped if the tool bar cannot be lifted up, the internal burr is periodically scraped, and the shape of fish scale and spiral.

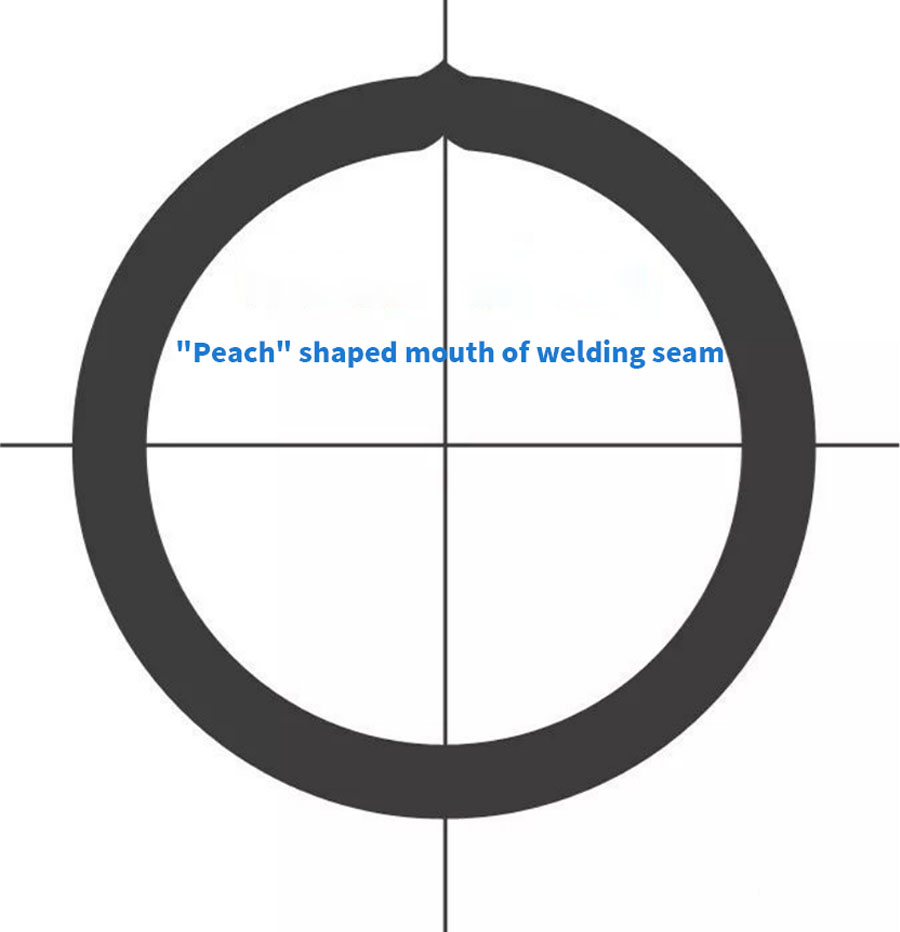

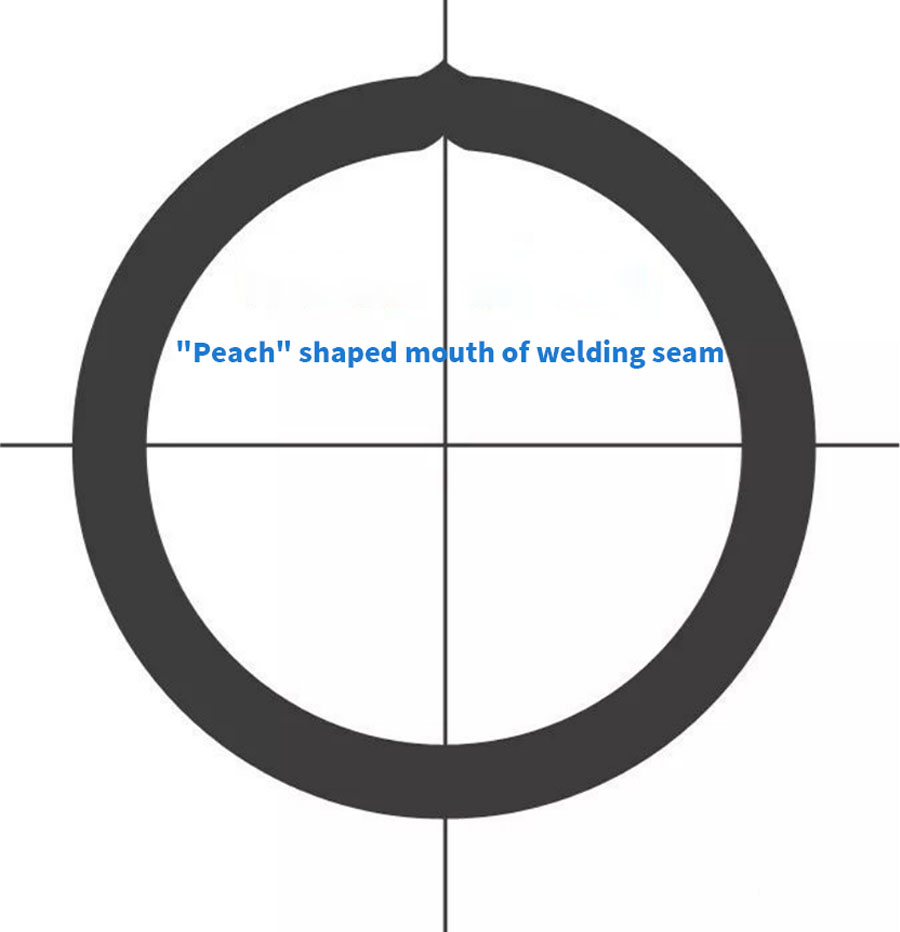

Welds are peach-shaped:

After the steel pipe below φ165mm is welded, the weld exists in the shape of "peach", as shown in the figure below.

Solution:

Four-roll extrusion or three-roll extrusion is adopted. When producing steel pipes with a wall thickness of 4-14mm, the first deforming roll should fully deform the strip edge, and the tube blank after extrusion rolls will be flat and oval, so that the strip edge can be level. Butt welding. When producing steel pipes with a wall thickness of 0.4 to 2 mm, the first deforming roller should fully deform the edge of the strip, the bottom arc vertical ellipse is formed at the 6 frames with guide sheets, and the bottom arc flat ellipse is formed at the 7 frames and 8 frames with guide sheets; two When the roller is extruded, the circular arc of the tube blank after extruding the roller is a flat ellipse.

The blade can't be lifted, and the burr can't be scraped

Cause: The lower roller frame is stuck with metal iron oxide slag and cannot rise and fall.

Solution:

①Clean the lower roller frame or replace it with a new lower roller frame to make it move up and down flexibly.

② Check whether the hydraulic system, oil pipe, and relief valve are blocked and cannot pass oil, whether the reversing valve is reversed, whether the hydraulic pump is working and other.

If the above two items are completely normal, the tool bar still cannot be raised and no burrs can be scraped.

The main reasons for this problem are:

①The outer diameter of the guide piece is too large to withstand the tool bar, so that the tool bar cannot be raised to the position.

Solution: reduce the outer diameter of the guide piece.

②The fixing plate at the end fixed on the adjusting device is lifted up too high.

Solution: Lower the fixing plate on the adjustment device to a reasonable position.

Internal burr scraping is periodic, scale-like and spiral-like

The internal burr scraping changes periodically, the reasons for this problem are:

①There are iron lumps on the groove in the middle of the lower roller, which makes the lower roller periodically jump up and down when it rotates.

②Relief valve and hydraulic pump are broken so that the pressure changes periodically.

Solution: Replace the lower roller of the used roll forming equipment; replace the new overflow valve and hydraulic pump.

The scraped inner burr is scaly, the reason for this problem:

①The cylindrical grinding of the lower roller has a flat surface. Solve to replace the new lower roller.

②The hydraulic pressure varies between ±0.2 MPa. The solution is to replace the relief valve with a new one.

The shape of the scraped inner burr is spiral or tower spiral, the reason for this problem:

①The welding seam is deflected to one side, and the strip camber is bent too much.

Solution: Adjust the pressure of the upper rollers supported by the flat rollers of the left and right arch frames of the sizing machine to force the weld to be straightened.

②The welding seam swings left and right, and the strip scythe bends greatly, especially the serious wave bending at the head and tail of the strip.

Solution: Improve strip quality to reduce camber and wave.